|

|

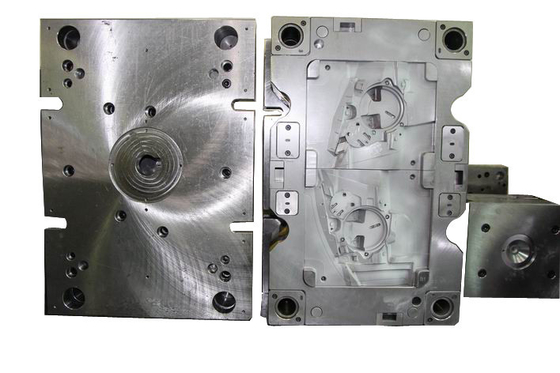

Hot Cold Runner Two Shot Mold

|

Product Details:

Payment & Shipping Terms:

|

| High Light: | two shot injection molding,Custom Injection Molding |

||

|---|---|---|---|

Hot Runner , Cold Runner Double Shot Injection Molding With Polishing / Grain Surface

Specifications:

|

1 |

Product Name |

Two Shots Injection Mold |

|

2 |

Mould Base |

LKM / HASCO / DME etc. |

|

3 |

Mould Core |

1.2343 ,1.2767,S136,H13,P20etc. |

|

4 |

Cavity |

Single Cavity, Multi Cavity |

|

5 |

Runner |

Hot Runner, Cold Runner |

|

6 |

Gate |

Side gate, pin gate and submarine gate |

|

7 |

Surface Finish |

Polish, grain |

|

8 |

Design Software |

CAD, UG, PROE, etc |

|

9 |

Product Material |

PA6+25%GF,PC+ABS, PC,ABS,TPE,TPV, etc |

|

10 |

Mould Life |

300, 000 shoots |

|

11 |

Package |

Inner for PP bag, outer is wooden case. |

|

12 |

Delivery Time |

35~45 days for mould, and 7~10 days for design. |

Description:

The molded products’ material can be PA6+25%GF,PC+ABS, PC,ABS,TPE,TPV and so on.

Mold base LKM / HASCO / DME etc.

Mold material:1.2343 ,1.2767,S136,H13,P20 etc.

Mold material: S136, 1.2344, H13, 1.2767, P20 etc.

Surface treatment of the mold: polishing and grain surface

Cavity type: single cavity or multiple cavities

Runner system: hot runner and cold runner

Dimension of the mold: can be made by customers designs

Mold life: 300,000 shots

Designed software: UG, CAD, PROE

Mold processing: CNC / Cutting / Carved / EDM/Milling/Threading/Drilling, etc.

Arrangement type: I-section / Straight Body Mould

Project developing procedure:DFM---- 2D structure design----3D design-----mold machined and processed----testing --delivery

I Injection molding is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed and forced into a mold cavity where it cools and hardens to the configuration of the cavity.

Injection molding is widely used for manufacturing a variety of parts from the smallest component to entire body panels of cars.

It can be used from home appliance to electronic parts.

Ahead Mold is competent in offering a wide scope of injection molding service to customers. We can meet your specific requirements in terms of material, size, complexity and volume.

The advantages of Ahead injection molding are:

1. a high molding speed adapted for mass production.

2. multiple choices of thermoplastic material, can provide a variety of useful properties.

3. large productivity for mold threading, undercutting, holes drilling

4. within 24 hours reply and timely reply

5. competitive price and reasonable designs

-

Lathe Steel Fabrication / Heavy Duty Precision Machining Steel Fabrication

-

2 / Two Shot Moulding OEM Plastic Overmolding , Over Moulded Plastic Handle tool

-

Automatic pvc injection moulding machine 430Ton 150rpm

-

PC Plastic Injection Moulding For Electrical Switch Box Covers

-

OEM Wire Cut EDM Process Precision Components For Connector Mould

-

Customized Bleed Valves for Pump , Plastic Injection Mould Parts