|

|

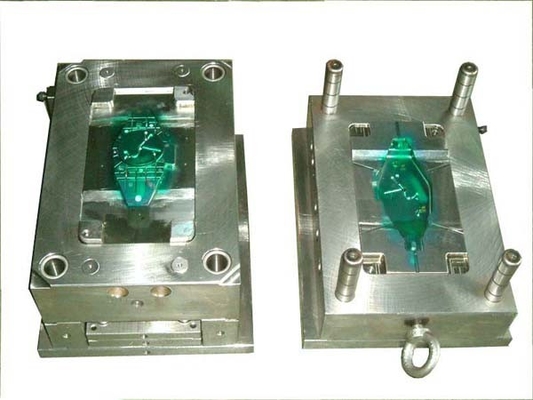

ABS HDPE PC PVC Cold Runner Mold EDM , Double Color Mould With Multi Cavity

|

Product Details:

Payment & Shipping Terms:

|

| Plastic Modling Type: | Injection Plastic Mould | Product Name: | Cold Runner Mold |

|---|---|---|---|

| Applied Software: | Pro/E, UG, Auto-Cad, Solid Work, CAM | Cavity: | Single Mould, Multi Mould |

| Design Software: | UG, PROE, CAD | Main Processing Equipment: | LKM, DME, HASCO |

| Mould Material: | P20, 718, 2083, SKD61, Raw PE, PP | Mould Runner: | Cold Runner |

| Processing Trade Form: | OEM, ODM | Product Material: | ABS, PP, PC, PE, PPS, HDPE |

| Surface Treatment: | Logo Print, Texture, Polishing, Painting, Chrome Plating | ||

| High Light: | metal injection moulding,cold runner injection molding |

||

ABS HDPE PC PVC Cold Runner Mold EDM , Double Color Mould With Multi Cavity

Quick Detail:

1. Shaping Mode: Plastic Injection Mould;

2. Mould Material: Quenched S136;

3. Runner System: Cold Runner;

4. Cavity Layout: Single;

5.Raw Material: ABS;

6. Tolerance: ±0.02mm

Description:

|

Place of Origin |

Dong Guan City, China |

|

Core Business |

Plastic mould making and injection molding service |

|

Design software |

UG, ProE, CAD |

|

Maximum mould size |

2,000*1,500*1,000mm |

|

Mold build capability |

Up to 20Ton |

|

Clamp forces |

60Tons~400Tons |

|

Cavity |

Single-cavity, multi-cavity |

|

Certificate |

ISO9001:2008 and SGS |

|

Mould material |

718H, P20, NAK80, S316, S50C |

|

Raw Material |

ABS, PP, PC, PVC, POM, |

|

Mould Structure |

Insert Mould, Over Mould, Double Color Mould etc |

|

Mould base |

HASCO,DME,LKM standard |

|

Processing Craft |

Milling, Grinding, Drilling, Engraving, EDM, Wire Cutting, Polishing |

|

Tolerance |

±0.02mm |

|

Gate type |

Cold runner, Hot runner |

|

Appearance finished |

EDM, High polish; Mirror polishing, Texture/Graining |

|

Mould Life |

30,000 to 1,000,000 shots |

|

Hardness of steel |

18~56 HRC |

|

Delivery time |

2 to 8 weeks ( According to the structure) |

|

Package |

Wooden Box or as required |

|

Delivery term |

FOB SHEN ZHEN |

Applications:

This product is a frame for a electronic part, the precision is high and the part structure is complicate,

many mould slide and inserts in it.

We can customize diverse moulds for our clients based on the 3D drawing they provide, such as the electronic part mould, plastic injection mould, die-casting mould and so on.

Specifications:

|

1.Quote |

According to sample, drawing and specific requirement. |

|

↓ |

|

|

2.Discussion |

Mold material, cavity number, price, runner, payment, etc. |

|

↓ |

|

|

3.S/C Signature |

Approval for all the items |

|

↓ |

|

|

4. Advance |

Pay 50% by T/T |

|

↓ |

|

|

5.Product Design Checking |

We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

|

↓ |

|

|

6.Mould Design |

We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

|

↓ |

|

|

7.Mold Tooling |

We start to make mold after mold design confirmed |

|

↓ |

|

|

8.Mold Processing |

Send report to customer once each week |

|

↓ |

|

|

9.Mold Testing |

Send trial samples and try-out report to customer for confirmation |

|

↓ |

|

|

10. Mold Modification |

According to customer’s feedback |

|

↓ |

|

|

11.Balance settlement |

50% by T/T after the customer approved the trial sample and mould quality. |

|

↓ |

|

|

12.Delivery |

Delivery(mould,3D and 2D drawing ,spare parts) by sea or air. The forwarder can be designated by your side. |

Competitive Advantage:

1.High quality

2.On time delivery

3.Good After-sale service

4.We have cooperated with many well-known international companies.

5.Professional technique team.10 engineers,>30technician.

6.Advanced equipment: CNC; Numerical control machine ,Milling machine, Precision grinder, EDM,

Plastic injection machine, ect.

7.Professional service.

8.ISO9001:2008 approval.

9.competitive price

-

Cold Runner Injection Molding Auto Part Mould

-

ABS Plastic Injection Mold Cold Runner , 4 Plate Printer Component

-

OEM / ODM Standard Injection Mould Cold Runner Mold For Plastic Pipe

-

Multi Cavity Double Injection Mold Hot Runner Mold With P20 Mold Base

-

OEM ABS+PC Material Hot / Cold Runner Plastic Molded Parts For Switch

-

Hot Runner And Cold Runner Transparent Mold / Molding LKM / HASCO / DME