|

|

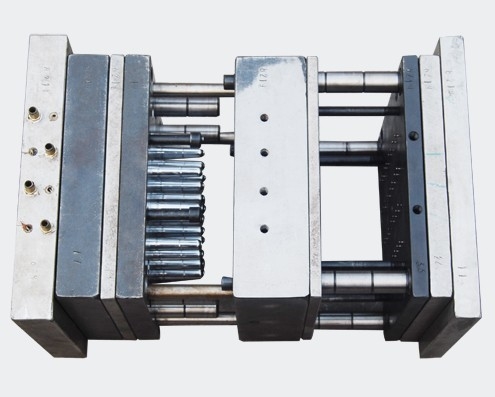

High Precision Medical Injection Molding Medical Machine Parts Die Casting Mould

|

Product Details:

|

Detailed Product Description

| High Light: | custom plastic molding,custom plastic molds |

||

|---|---|---|---|

Contact Details

China Plastic Injection Moulds Online Market

Send your inquiry directly to us

More Medical Injection Moulding

-

PVC / UPVC Plastic Injection Mouldings Part for Drawing, Mechanical and Auto

-

Custom Hot Runner Medical Injection Molding , Plastic Injection Moulding Process

-

High Polish Medical Injection Molding , PP PE PC PVC Plastic Mould Maker For Medical Parts

-

Medical Appliances Plastic Injection Mold Making / Custom Plastic Injection Tooling

-

Custom / OEM PVC, CPVC, PVDF, PP, PE, ABS, PTFE Plastic Injection Mouldings

-

Customized Professional Medical Injection Molding / Plastic Injection Moulding Services