|

|

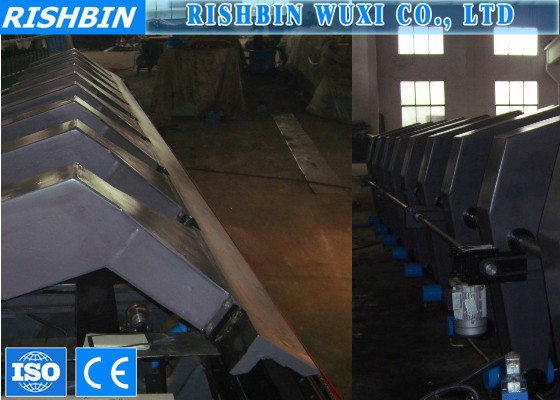

Curving Machine CNC Metal Cold Roll Forming Machine For Fold and Slit Work Piece

|

Product Details:

Payment & Shipping Terms:

|

| Throat Depth: | 800mm | Max. Folding Thickness: | 1.50mm Steel @ 250mpa |

|---|---|---|---|

| Max. Slitting Thickness: | 1.00mm Stainless Steel | Slitting Mold: | Rotary Slitter |

| Model: | RH-CR-130 | Color: | Blue Or Client's Demand |

| High Light: | metal roll forming machines,steel roll forming machine |

||

Specifications of CNC metal cold roll forming machine

|

Max. folding length |

6500mm |

|

Throat depth |

800mm |

|

Max. folding thickness |

1.50mm steel @ 250mpa |

|

2.00mm soft aluminum |

|

|

1.00mm stainless steel |

|

|

Max. slitting thickness |

1.50mm steel @ 250mpa |

|

2.00mm soft aluminum |

|

|

1.00mm stainless steel |

|

|

Max. folding angle |

125 degrees |

| Motor | 5.5KW |

|

Weight |

12MT |

|

Slitting speed |

About 800mm/second |

|

Slitting mold |

Rotary slitter |

|

Control system |

PC with 12’’ LCD |

|

Electric condition |

380V/3Phase/ 50HZ |

Component of CNC metal cold roll forming machine

- Machine body 1pc

- Digital-control backstop 1set

- Slitting system 1set

- Work piece supporting equipment 1set

- Clamp unit 1set

- Folding equipment 1set

- Hydraulic system 1set

- PLC Control system 1pc

Quick detail of CNC metal cold roll forming machine

- Unique electric / hydraulic control ensures safe and simple operation

- Bending beam powered by dual hydraulic cylinders

- Fully integrated and enclosed electric / hydraulic system with large oil reservoir to maintain low oil temperature

- High quality componentry ensures reliable performance for years of continuous operation

- Powerful direct coupled hydraulic pump and motor provides efficient, rapid operation

- Easy & Quick setting

- High load capacity dual spherical plane bearings utilized at bending beam pivots and over-centre clamp bearings

- Programmable Controller both bending angle and back gauge

- Hydraulically operated bending and clamping beam for efficient heavy duty operation

- Box and pan sliding style tooling

- Accurate repetition & bending

- User friendly Hydraulically operated bending and clamping beam for efficient heavy duty operation

- High structural rigidity from heavy plate steel box construction with continuous welded seams

- Comprehensive equipment protection from electric and hydraulic overload systems

- Precise electric / hydraulic controls with manual inching of bending beam

- Enormous versatility

This machine is used to crimp the formed corrugated sheets into horizontal stripes through hydraulic crimping mold. This distance between each press will decide the curvature of the arch. It is suitable for edge of buildings, parking garge, pavilion and various round roofs of buildings.

Applications

- It is a long folder with features below

- Torsion Shaft: on both the clamping and folding beams prevents uneven clamping

- Free Space for Forming: has more free space than any long folder on the market

- Graphical Control: manages type, thickness, backgauge position, bend angle and more

Competitive advantage

· Reasonable design

· Reliable

· Durable

· Longer folder

· Enormous versatility

· Easy & Quick setting

Company introduction

Rishbin was founded in 1999. With more than ten years' development, now it becomes a leading professional supplier in the field of roll forming machinery industry, and exports its quality production line to the markets all over the world.

we are one of the leading suppliers and manufacturer in china and have been supplying and making roll forming equipment for the metal building construction industry for a long time.

Contact us

For more information, please contact us freely.

Skype: sarahrishbin

Mobile: +86-18118899986

E-mail: sarahrishbin@gmail.com

-

6090 Desktop CNC Router Machine with CE

-

Rapid Prototyping Aluminum Cnc Precision Metal Machining Parts

-

Custom Made Aluminum Alloy A380 Zinc Die Casting High Precision CNC Metal Machining

-

NC Custom Metal Machining With Nature Anodizing Aluminum Material

-

Precision 5 Axis Machining Aluminum 5052 Stainless Milling Parts

-

Brass Custom Metal Machining Service Precision Mechanical Components