|

|

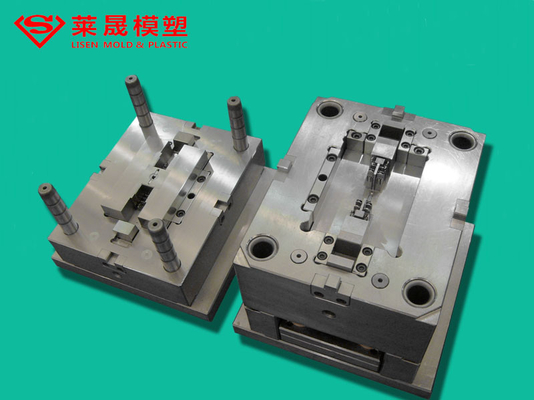

Plastic Injection Mould for Medical Parts

|

Product Details:

Payment & Shipping Terms:

|

Detailed Product Description

| High Light: | Plastic Injection Mould,plastic mould,plastic mold |

||

|---|---|---|---|

| Company Introduction: |

| Established in 2012, Xiamen Lisen Mold & Plastic Engineering Co., Ltd specializing in high precision plastic mold andplastic injection molding from prototyping to high volume productionfor precision electrical parts and medical treatments, plastic food parts, telecommunication device, toys and crafts. |

| Covering 2,000 square meters, we hae one stop precision tooling shop and injection center with 100,000 grade clearing room, turnkey service including product design assistance, mold design and fabrication, production and assembly. |

| Company Advantage: |

| 1- 2 Years OEM and ODM experience in plastic mold and injection molding service for Electrical parts, Medical treatments, Auto |

| Parts, plastic food accessories, Telecommunication devices, Toys and Crafts: One stop tooling room and injection center. |

| 2- Advanced equipment and professional technology: CNC, CMM, precision tooling room and injection machines with 100,000 |

| classes cleaning injection room. |

| 3- Advanced R&D service and Best Engineer: DFM, Mold Flow Analysis and Project Design Assistance. |

| 4- Excellent and Nice IML (In Mold Labeling) technology, we can manufacture the IML moulds. |

| 5- Quality and Price: Quality-oriented and cost drivers analysis to share cost reduction with customers. |

| 6- Series service of design, prototyping, painting, printing and simple assembly. |

| R&D Capabilities |

| 1. To meet high standard of product quality you required, we perform our production under 5S management system and ISO9001:2008 standards. |

| 2. Apply the latest CAD/CAM technology in Design, Tooling and Engineering. Team work of Designers and Technicians, Skilled in Using 2D /3D Software (Pro-E, Auto CAD and Solidworks) |

| 3. We offer: DFM, Mold Flow Analysis and Project Design Assistance. |

| Business Scope: |

| 1. Plastic Parts Designing & Manufacturing. |

| 2. Plastic Injection Mould Designing & Manufacturing. |

| 3. Reverse Mould Engineering |

| 4. Rapid Prototyping |

| 5. Injection Molding with 100,000Grade Purification Injection Workshop |

| 6. Product Treatment & Product Assembling |

| 7. OEM & ODM are warmly welcomed |

| Mold Parameter Information: | |

| Mould standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

| Mould base | LKM & Hasco & DME standard (A,B plate 1730,2311,2312,P20 ) |

| Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| Hardness of steel | 46~56HRC |

| Material for Slider ,Lifter and all sub insert use | 1.2767 HRC |

| Cavity | Single-cavity or Multi-cavity (Customized) |

| A surface request | EDM & High Polish & Texture |

| Mould Gate | Hot runner or Cold Runner |

| Mould life time | 500000~+1,000,000 shots |

| Package | Wooden case for tool ,PE bags add export carton for parts |

| Value-added service | Mold, injection, painting, silk printing, assembly full product |

| Mould leading time | 25-45days (need to see product structure,size..). |

| Hot runner advantages | No gate,no waste plastic material,save much more holding time |

| Our advantages | Quick delivery, precision mould making, 100,000 Grade Purification Injection Workshop |

| Plastic Material for injection mould | Nylon, ABS, PMMA, PP, POM, PP, PE, PC, PBT, PA, PSU, TPU, TPE, etc.. |

| Fit for | Electrical parts, Medical treatments, Food accessories, Telecommunication devices, Toys and Crafts etc., |

| Mould tolerance | 0.003-0.05mm |

| Software for mould | Pro-E (igs, stp, x-t), Solidwork, Auto CAD, UG. |

| Payment Term | |

| Payment term | 1. For the mold: 50% deposit, 50% balance after confirming the samples or before delivery. |

| 2. For the injection parts: 30% deposit, another 70% balance paid before shipping. | |

| Trade terms | FOB XIAMEN |

| Packing detail | Standard Export Packaging |

| For the mould: Wooden Case. | |

| For the production: Polybag, gift box, master carton etc., It depends on customers' requirements. | |

| Delivery Detail: | For the export mold: About 25-45 days after confirming the mold drawings for T1 samples. |

| For the injection production: About 20-45 days according to the quantity. |

![]()

![]()

![]()

Contact Details

China Plastic Injection Moulds Online Market

Send your inquiry directly to us

More Medical Injection Moulding

-

PVC / UPVC Plastic Injection Mouldings Part for Drawing, Mechanical and Auto

-

Custom Hot Runner Medical Injection Molding , Plastic Injection Moulding Process

-

High Precision Medical Injection Molding Medical Machine Parts Die Casting Mould

-

High Polish Medical Injection Molding , PP PE PC PVC Plastic Mould Maker For Medical Parts

-

Medical Appliances Plastic Injection Mold Making / Custom Plastic Injection Tooling

-

Custom / OEM PVC, CPVC, PVDF, PP, PE, ABS, PTFE Plastic Injection Mouldings