|

|

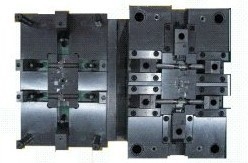

HASCO / DME Custom Injection Molded Plastics Injection Molding

|

Product Details:

|

| High Light: | custom injection molding,husky injection molding,custom injection moulding |

||

|---|---|---|---|

HASCO / DME Custom Injection Molded Plastics Injection Molding

Quick Detail:

Precision Injection Mould,Accept Any Customized Dimension,Widely Used Application,High Quality Mould,Best Service

Description:

1) Mold design: Mold design according to your product drawing or sample.

2) Steel material: P20, 718, NAK80, S136, SKD11, 8407, 1.2363 or customers' appointed material.

3) Mold type: Plastic mold, hot runner mold, double injection mold, insert mold, rubber mold, die casting mold, stamping mold.

Injection Mould are applicated in various industrial areas, such us automotive,medical,electronic,computer,

office automation,mobile phone,EAS security ,industrial instrument ,and household appliances.Plastic Injection Mould products are cover all our daily life,TV,Refrigerator,car, drink bottle,toys,all could not produce without injection mould.With a shape,need a mould.

Our KeTech Mould accept all kinds of customized mould for each customer as per their requirements. The quotation we can quote base on drawings or samples provided by the customers. Our products are both

excellent in quality and reasonable in price.Your satisfaction is guarantee.

Specifications:

|

Mold steel |

P20, H13, 718H, 2738, SKD61, NAK80, 8407, S136H, etc |

|

Plastic material |

ABS, PC, PE, PP, HDPE, PPR, PVC, PBT, PS, PET, etc |

|

Mold base |

LKM, HASCO, etc |

|

Mold runner |

Cold runner and Hot runner, etc |

|

Mold Hot runner |

DME, HASCO, YUDO, etc |

|

Mold cold runner |

Point way, side way, follow way, direct gate way, etc |

|

Mold standard parts |

DME, HASCO, etc |

|

Mold life |

It mainly depends on various kinds of steel. |

|

Design software |

Solid work, UG, PRO-E, CAD, etc |

|

Mold doff way |

Doff plate, ejectors, air valves, hydraulic jar, etc |

|

Mold hot treatment |

Including quencher, tempering, etc |

|

Mold cooling system |

Water cooling or Beryllium bronze colling, etc |

|

Process |

CNC milling center high speed, EDM machine (Taiwan), wire cut (Sodick), etc |

|

Mold shipment |

By Express,By sea, By air etc |

|

Mold packing |

Standard Export Packing Or Per Customer Requirements |

Competitive Advantage:

Advanced technology with competitive price,Excellent mold designer team,High production capacity,Prompt delivery time,Perfect after-sales service

-

Dust / Humidity Resistant Custom Injection Molding In Mould Decoration

-

PET / TPE / PVC / HDPE Custom Injection Molding , Multi Cavity IMD Mould

-

Single Cavity Precision IMD Mold , ABS / POM / PMMA / PC Injection Mould

-

Export Competitive High Precision Custom Injection Mold For Electronic Product

-

H13 Cavity Grinding IMD Molding LKM Standard S136 Flexible

-

Customized Injection Molded Products Mosquito Trap with LED and Attractant Brew