|

|

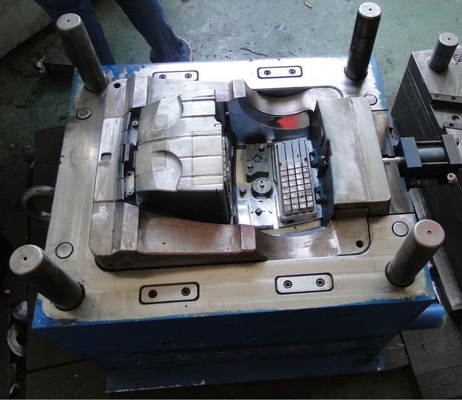

Plastic Injection Home Appliance Mould For Vaccum , Custom Injection Mold Products

|

Product Details:

Payment & Shipping Terms:

|

| Shaping Mode: | Plastic Injection Mould | Product Material: | STEEL |

|---|---|---|---|

| Mould: | Plastic Injection Mould For Vaccum | Cavity: | Single / Multi |

| Runner System: | Hot & Cold | Mold Base: | LKM, HASCO Etc |

| Mold Material: | 738H 718H NAK80 S136 2344 | Modl Life: | 500,000~1,000,000 |

| Design Software: | PROE, CAD, CAM,CAE Etc. | Design: | ODM Plastic Mould Parts Design |

| Offer: | OEM/ODM | Shipment: | By Sea Or Air , Or Express |

| Product: | Plastic Parts | ||

| High Light: | plastic injection moulding products,plastic injection tooling |

||

Plastic Injection Mould For Vaccum Plastic Injection Mould Products from China (Mainland)

Specifications

1) we design kinds of vacumm machine mould.

2) advanced technology and manage

3) different runner

4) standard moul base

Shenzhen Yonghe Tai Technology Co.,LTD is a professional in making mold and plastic products, If you need mold or products, we can help you to do this, but first please send us more and more information about the mould what you have. Like sample photo, sample size, what's the sample material and what kind of steel you want to make the mould, When we get this information, we can send the mould quote andTechnology analysis.

Our Factory Advantages

1. We are one_stop manufacturer of plastic mold and finished plastic products. Specialized in mold design, making plastic mold, injection process,spraying and silk printing.one-stop services for more than 9 years.

2. We can make molds and plastic products according to your drawings or samples.

3. Our die include: auto parts, household appliances, medical equipment, House application products, electronic and electrical appliances, handicrafts and engineering construction etc...

4. Injection products material character:soft plastic,hard plastic,transparent,ect.

5. Common used plastic material:ABS,PC ,TPR,TPU,PMMA,POM,PA,PP,BPT etc.

TECHNICAL SPECIFICATIONS

| roduct Name | Auto plastic parts injection mould |

| Product material | ABS,PP |

| Core&Cavity Steel | 718 |

| Steel hardness: | HRC34-38 |

| Mould Standard | DME |

| Cavity Number | SINGLE OR MULTI |

| Injection System | SIDE GATE |

| Ejector System | EJECTOR PIN |

| Cycle Time | 30S |

| Tooling lead time | 50DAYS |

| Mould life | MORE THAN 500,000SHOTS |

| Quality assurance | ISO9001 |

| Our Advantage | 1.High quality |

| 2.Reasonable price | |

| 3.On time delivery | |

| 4.Good After-sale service | |

| 5.Strict quality control | |

| 6.All the mould are automotic. | |

| Offer you | In-time response on letters, telephone calls or fax |

| In-time supply the quotation and mould designs | |

| In-time communication on the technical points | |

| In-time sending pictures for the mould machining progress and mould finishing schedule | |

| In-time mould test and sample delivery | |

| In-time mould delivery. |

Custom Your Own Mould

Mould Trade Process :

|

1.R&D |

We support customer R&D. Make the files or improve the design if you needed |

|

↓↓↓ |

|

|

2.Quotation Making |

Mould Quotation will be finished in 1day according to information we get |

|

↓↓↓ |

|

|

3.Negotiation |

The quality ,price ,material,delivery time .payment item.ect |

|

↓↓↓ |

|

|

4.Mould Design |

3-5days for mould and product 3D/2D drawing design |

|

↓↓↓ |

|

|

5.Mould |

According to customers' request to build the mould.Before make the mould .we send mould design to customer approval first . Mould will be usually finished in 40-50days |

|

↓↓↓ |

|

|

6.Mould Testing |

When moulds are finished,we will test the moulds to check it satified consumers' needs.And we will send samples for consumers' reference. |

|

↓↓↓ |

|

|

7.Sampleshoot |

If the first sample come out is not satisfied customer .we modify the mould and until meet customers satisfactory |

|

↓↓↓ |

|

|

8.Delivery |

Delivery goods by sea or by air ,according customers requirement |

![]()

![]()

![]()

![]()

Packaging & Delivery

Packaging Detail:Wooden box for moulds;Exports standard carton for products.

Delivery Detail: 28-35days

![]()

![]()

-

Plastic Injection Mold Machine With Auto Parts / Home Appliance Mould

-

High Speed Size 2# 3# Automatic Capsule Filling Machine With PLC Control NJP-1200

-

Metal Steel Die Casting Components , Aluminium Pressure Automobile Casting Parts

-

VALTOO mould/home appliances mould/toilet bowl mould/toilet plastic/toilet bowl mold

-

Silver Aluminum Foil Baking Pans Divided Custom Aluminum Foil Container

-

Black High Elasticity Rubber Shock Mounts / Anti Vibration Machine Mounts