|

|

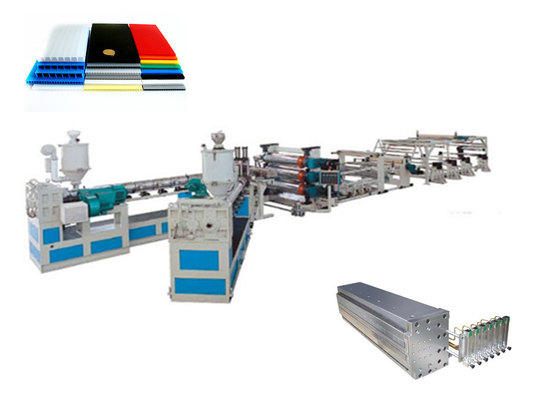

SJ120 / 30 Plastic Sheet Extruder / PP PC Hollow Roofing Sheet Extrusion Line

|

Product Details:

Payment & Shipping Terms:

|

| High Light: | sheet extrusion machine,pvc sheet extrusion line |

||

|---|---|---|---|

SJ120 / 30 Plastic Sheet Extruder / PP PC Hollow Roofing Sheet Extrusion Line

Quick Detail:

The PP PC hollow plastic sheet machine is mechanotronics, with the advantages of:

1) high production efficiency;

2) reasonable structure compact;

3) convenient operation and maintenance

4) long use life etc.

Description:

|

Main extruder |

SJ120/38+SJ 45/30 |

SJ100/38+SJ45/30 |

SJ120/30 |

SJ90/30 |

|

Raw material |

PC |

PC |

PP,PE |

PP,PE |

|

Width of finished product |

2100mm |

1300mm |

2100mm |

1300mm |

|

thickness of finished product |

2-40mm |

2-10mm |

2-8mm |

2-8mm |

|

Main drive power |

185/22kw |

132/22 kw |

132 kw |

110 kw |

The PP PC hollow plastic sheet machine is consisted by following items:

1. Single-screw extruder;

2. Automatic screen changer filter;

3. The extrusion die for the hollow sheet(T-die);

4. Calibration device with vacuum;

5. First haul-off device and edge cutter;

6. Oven device;

7. Laminating device for the surface protection;

8. Second haul-off device and edger cutter;

9. Auto-cutter device with metering system;

10. Sheet feeding device;

11. Stacker

Competitive Advantage:

You can use different extrusion die and calibration mould with relevant extruder screw to produce different sheet like by PE,PP,PC material .

The upper lips and lower lips can regulate the thinkness of the prouducts,and can satisfy of different thickness products,with blowing device.

All sides of the mould plated chromium and used high-strength bolts with 12.9 grade.The heater make of nice stainess can be control heating. Steady production,the structure is simple, easy to remove and cleaning.

Applications:

The PP PC hollow plastic sheet extruder can produce PC sheet and PP hollow sheet.

Application of the PP hollow sheet:

PP hollow sheet is light , high strength, damp proof, good environmental protection and secondary processing; can produce to container, packing case, clapboard, base plate; it is widely used in electric,home appliance,suitcase,machinery,post,food,medical,pesticides and advertisement,decoration and some other areas.

Application of PC sheet:

it has a good lighting advantage, widely used in office building,hall,market,sports stadiums,entertainment center and public service; canopy for station,parking lot,arbor,lounge hall corridor; airport and factory,cover for modern agriculture,farming industry and indoor swimming poor; used in high way billboard and separate office from private room and separate show room from washroom when displaying and exhibition.

plastic sheet machine, plastic sheet extruder

-

Plastic Injection Mold Machine With Auto Parts / Home Appliance Mould

-

High Speed Size 2# 3# Automatic Capsule Filling Machine With PLC Control NJP-1200

-

Metal Steel Die Casting Components , Aluminium Pressure Automobile Casting Parts

-

VALTOO mould/home appliances mould/toilet bowl mould/toilet plastic/toilet bowl mold

-

Silver Aluminum Foil Baking Pans Divided Custom Aluminum Foil Container

-

Black High Elasticity Rubber Shock Mounts / Anti Vibration Machine Mounts